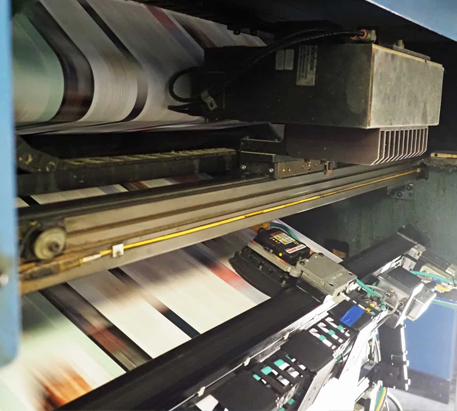

Baldwin manufactures technologies that automate and enhance print-production processes, from offset to flexography and corrugated.

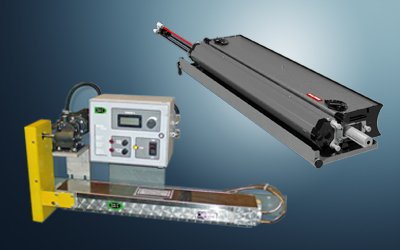

From LED and UV curing systems through web process controls, color inspection software and fluid management technologies, we manufacture the solutions printers use every day to increase their productivity, quality and profitability.

Baldwin Technology Company has manufactured novel process automation and enhancement solutions used in the printing industry for more than 100 years - our experience building systems that work with printing presses of all kinds is unmatched by our competitors. The company’s first product was the Baldwin Press Washer, which reinvented the pressroom process by giving printers a way to automatically clean their press. Today, we offer a host of solutions for printing, including equipment for:

Some of the printing segments our equipment is designed for include:

web offset lithography

sheetfed offset litho

inline narrow and mid web flexography

central impression (CI) web flexo

web rotogravure

sheetfed corrugated flexo

sheetfed inkjet

web inkjet

When it comes to engineering equipment that works with printing presses, Baldwin’s team are experts at engineering solutions for almost every make and model of press imaginable - and because of our firm understanding of how different types of presses work, we offer a level of expertise that can’t be replicated.

Find out more about our various solutions for printing below - if you are unsure if one of our process automation and enhancement technologies is applicable for your requirement, feel free to contact us to learn more.