Baldwin builds surface-cleaning systems that help printers, film extrusion specialists and other manufacturers automate difficult cleaning tasks.

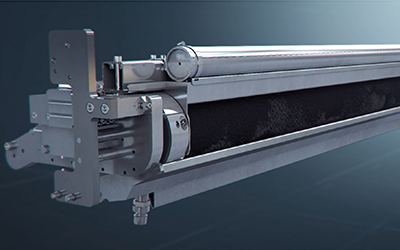

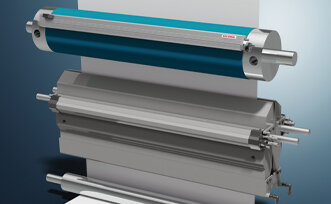

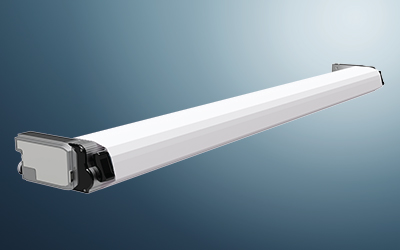

Our solutions automatically and safely clean cylinders, blankets and plates used in various production processes, and tackle cleaning tasks like hickey-picking, end-of-run plate cleaning, blanket cleaning and film cylinder cleaning to save time, money and resources while producing higher-quality products.

Our surface cleaning systems are used to automatically clean the surfaces of printing plates, blankets, film cylinders and other devices that apply chemistries like inks, coatings and solutions to surfaces, so that operators do not have to complete these dangerous and and difficult cleaning tasks manually. By automating these processes, operators of printing presses and film extrusion lines can use fewer chemicals, save water, increase production speeds, reduce waste and keep their staff safer.

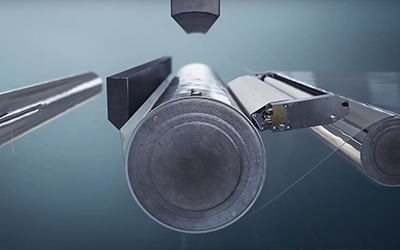

Baldwin has been manufacturing surface-cleaning technologies for decades, and is well-known in the offset printing industry for its solutions. The company’s automatic cleaning systems for film extrusion are industry-leading and offer a solution to the common problem of how to properly clean film cylinders consistently and without risk to the operator.

Baldwin’s surface-cleaning technology is used in a host of industries, including:

Web Offset Printing

Sheetfed Offset Printing

Newsprint

Corrugated Printing

Film Extrusion

Flexible Packaging

Can Printing

What Our Customers Say:

Our system was installed last fall and is doing everything Baldwin promised it would.

“We are all very excited to have Baldwin’s FlexoCleanerBrush system installed on our new Göpfert Ovation press. I’ve had the opportunity to see this system in action at a couple locations and was very impressed. Our system was installed last fall and is doing everything they promised it would. It has dramatically reduced our total plate washing time and allows us to pull the plates off the press at the end of run without any additional cleaning. Our operators are also utilizing the hickey picker function during runs which has increases our overall throughput. This new system is allowing us to provide a higher quality product to our customers and has eliminated a lot of downtime associated with cleaning plates during and after a job is completed.”

— Scott WIlcox, Advance Packaging, USA