Baldwin in Deutscher Drucker: The System Will Take Care of It

/B&K Offsetdruck in Ottersweier, Germany, specializes in complex web offset products such as highly finished magazine covers. For fast and reliable register results, one can rely on technology from Baldwin.

B&K Offsetdruck GmbH in Ottersweier is one of the highest-profile web offset printers in Germany. Three 16-page presses from Koenig & Bauer – two C16s and one C217, which were commissioned between 2005 and 2017 – produce, among others, highly finished covers for magazines. An inline finishing system from Scheffer, UV coating or the cutter with plano delivery require a level of skill and experience from the press operators that goes beyond the “printer's eye". To be able to concentrate on such complex auxiliary units during makeready and, of course, during production, these web offset presses have been equipped with register and colour control systems from Baldwin (formerly QuadTech) from the very beginning.

Hans Geideck, technical manager at the Baden-based flagship plant, is a pragmatist: “The biggest advantage of the systems is simply that the printer can take care of the overall product and does not have to worry about ink and register. It takes care of the rest of the machine and only at the end it looks at the colour and by then you are often already 80 to 90 per cent at the values you need for saleable products.”

Update also includes spectral measurement

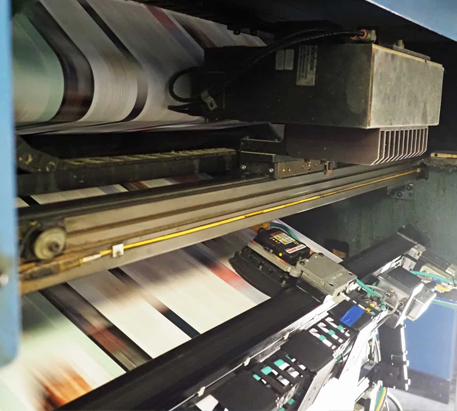

Easy to place: Baldwin's colour measurement (above) and register control systems.

With Baldwin, Geideck says he has “a good relationship based on partnership.” But B&K seldom needs more from this partner than the spare parts service staff, about whom the B&K technical director can also only say positive things. At present, the cooperation is somewhat more intensive: The register control system with MultiCam cameras and the Color Control System (CCS) were previously based on the Windows XP operating system and must be updated on both the hardware and software sides. The new MultiCams have already been installed and soon all presses will be equipped with Baldwin SpectralCam technology.

Baldwin's MultiCam are among the fastest in the industry – with up to 30 searching operations per second. The register control system's lenses are protected by the active OptiGuard system, which removes ink mist and dust from the lens. This ensures their performance even without major maintenance as the MultiCams detect the smallest register marks down to 0.36 mm, at a speed of up to 17.8 m/s. The small space requirement is also a feature of the CCS, which can handle a colour measurement patch or mark with a height of 1.6 mm. In practice, this means for B&K offset printing that printing can be done with a cut length of 620 mm instead of 630 mm, meaning lower costs are incurred for virtually every cylinder revolution.

The use of spectrophotometers has already proven successful at B&K on the newer presses. This makes it possible to measure spectrally, providing “real” Densitometric values rather than densities that can only be “estimated” by RGB sensors. In this respect, the system is the result of a necessary “update,” but also represents a genuine “upgrade.” Working with System Brunner also allows users of Baldwin equipment to work with grey balance instead of relying solely on solid densities and DeltaE values.

It is also helpful that all print jobs are logged by the Baldwin system. If register or colour values deviate to the point that this leads to a complaint, B&K can document exactly how many sections were affected.